Service description

Any business, small or large, knows that downtime due to equipment failures is cause for headache and dead-weight loss for your organization. We know it too. It's our goal to help you avoid this loss with our Planned Preventive Maintenance (PPM) programs.

Statistically, over half of all businesses wait until a problem occurs to have service completed, and nearly three-quarters of all equipment failure is a result of improper maintenance. PPM programs allow your organization the predictability of costs, prevention of equipment failure, and confidence in your equipment, which results in more working and less loss to your business.

Serving the Cleveland and Akron, Ohio region, our trained service technicians are ready to take on planned maintenance and loading dock equipment maintenance to reduce or even eliminate truck dock and facility down-time caused by equipment failure.

As longtime residents of the Cleveland area, we know that loading dock areas can take a beating from freezing temperatures and the build-up of snow and ice. Our loading dock equipment maintenance services can ensure your dock doors don’t stick or jam, your levelers are working, and your bumpers and trailer restraint systems are in top condition.

A preventative maintenance plan with Excel Solutions® ensures your dock doors, guide lights, levelers, and trailer restraints are all in good working order. We’ll make sure there are no excessively worn loading dock parts, and if there are, we’ll replace them. We can also service material handling and lift equipment to ensure you don’t have pallets stuck halfway up to their intended destination in your racks. With planned maintenance, you can stop equipment failures before they start, keeping your docks safe and your racks organized without delays caused by equipment failures. Call Excel Solutions® today to discuss a customized planned preventative maintenance program today.

Designed for End Users and Building Owners

- Increase operational efficiency and reliability

- Extend the useful life of your investment

- Reduce the probability of equipment malfunctioning†

- Decrease the incidence of costly downtime†

- Decrease long term repair expense†

- Establish a relationship with experienced, service oriented professionals

- Free your maintenance personnel to work on in-house equipment needs

† "Depending on the facilities current maintenance practices, present equipment reliability, and facility downtime, there is little doubt that many facilities purely reliant on reactive maintenance could save much more than 18% by instituting a proper preventive maintenance program." https://www.energy.gov/sites/prod/files/2013/10/f3/omguide_complete.pdf

If you're looking for local and first-rate loading dock equipment, high performance doors, or freight lifts in the Cleveland and Akron Ohio region, we are your solution.

Have a project? Let us know!

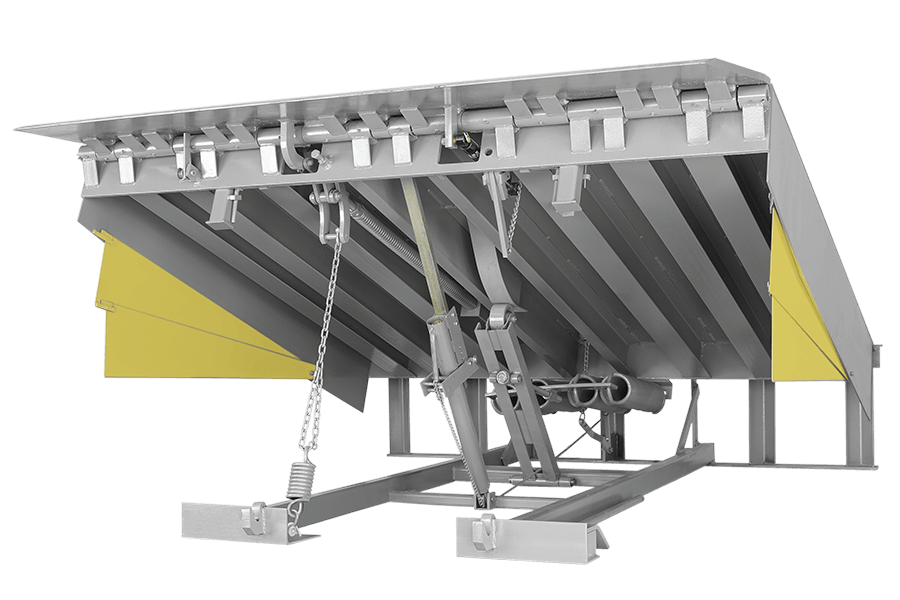

Dock Leveler Basics

A dock leveler is used in materials handling operations as a platform that rests on a truck or trailer bed to allow material movement at a loading dock.

Whether or not you already know it, a great deal of knowledge is required to outfit a facility with proper equipment and make sure it operates as intended. Instead of blindly delivering equipment, we gather the preliminary data necessary to provide the correctly spec’d equipment for your project. Doing so not only saves you in costs associated with efficiency, but it also ensures you receive the most from your purchase and keeps you from buying the product again prematurely. One great example is loading dock seals. Dock seals require custom fitting to your loading docks with many characteristics taken into account. Without the right information regarding your operations, incorrectly sized dock seals could be purchased and installed, leading to large building gaps and energy loss.

Your operations are unique to your production and facility needs to deliver an unmatched product, which begs the question: why shouldn’t your loading docks be unique as well? Your loading docks are the first and last area to see product and materials entering and leaving your facility. Excel understands the importance of efficient and safe operations, and has the people with knowledge and skills ready to deliver on an excellent loading dock design. Having a properly designed loading dock with the properly spec’d equipment not only reduces costs through energy savings and improved productivity, but it also saves you from replacing your equipment prematurely.

Dealing with an equipment supplier without properly trained technicians could be a large loss to your organization. Without knowledgeable technicians performing repairs on your equipment, problems with your equipment could go unsolved or missed and incorrect parts ordered, leading to losses in time and money. Excel only works with competent technicians without gouging our clients’ pockets – the only way to conduct business.

- Choosing a selection results in a full page refresh.

- Opens in a new window.