A trailer restraint, also known as a vehicle restraint system (VRS) or trailer restraint system, is a safety device used at loading docks to secure trucks and trailers during the loading and unloading process. The primary purpose of a trailer restraint is to prevent accidents caused by trailer creep, premature departure, and other movements that can occur when a trailer is not securely attached to the loading dock.

Original developed as a rotating hook design, they have risen in popularity since the 1980s. Modern trailer restraints have adopted a wide range of styles and activation systems.

The trailer restraint typically consists of mechanical or powered components that engage with the rear impact guard (RIG) of a truck or trailer. The RIG is a standardized metal structure located at the rear of most commercial trucks. By securely connecting to the RIG, the trailer restraint effectively immobilizes the trailer, ensuring that it remains firmly in place during the loading and unloading operations.

Types of Vehicle Restraints

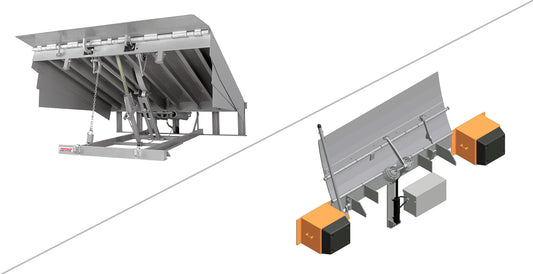

- Powered

- Powered vehicle restraints consist of a push button operator to activate the device and lock a trailer at the dock. They can be powered by various means, most commonly via an electric motor to rotate or activate the hooking device.

- Manual

- A manual restraint is activated by the user commonly using an activation rod. They are also stored by the user when done being used. They are available in a variety of designs, including rotating hook and vertical activating among others.

- Wheel Chock

- A wheel chock is a form of restraint wherein the driver of the truck places the chock to prevent trailer movement at the loading dock. It can be considered a manually activated restraint.

- Interlocked

- Interlocking is a method of restricting use of equipment without first following operating procedures as necessary for safe loading or unloading practices. Interlocking can be as simple as sequencing the signal lights (where present) even to preventing the activation of the dock plate without first activating the restraint. Interlocking is common on powered equipment.

- Signal Lights

- Signal lights are available with manual or powered restraints, and can be sequenced manually or automatically depending on the design of the restraint. Signal lights are also available as stand-alone units to aide in dock-driver communication.

Impact vs Non-Impact

- Impact

- Impact style restraints involve the trailer reversing into the restraint to position the restraint at the loading dock. From there, a worker can activate the restraint to prevent trailer departure from the dock.

- Non-Impact

- Non-impact are placed at the dock to be ready to capture a trailer when activated by personnel. They do not come in contact with the trailer first when being positioned, and generally only contact the trailer when activated by personnel.

Recessed vs Exposed

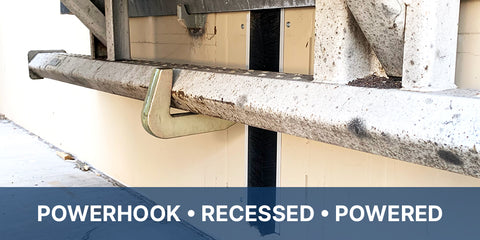

- Recessed

- Recessed restraints are great for snowy climates where snow pushing equipment is used at the dock. They are also great where driveway obstructions may occur such as drains. They offer a clean design and stay out of the way of other equipment.

- Exposed

- Exposed restraints are often the more cost-effective restraint. They are available in driveway or wall mounted designs depending on the application and style.

Reasons to Install a Restraint

- Worker Safety

- One of the primary purposes of a trailer restraint is to prevent accidents caused by trailer movement. Accidents such as trailer creep, premature departure, and tip-overs pose significant risks to dock workers, and a restraint system helps eliminate these dangers.

- Cargo Protection

- Unintended trailer movement can lead to cargo damage during loading and unloading. A trailer restraint ensures that the trailer remains securely in place, minimizing the risk of goods getting damaged.

- Preventing Trailer Tip-Over

- Some restraints are designed to prevent trailer tip-over incidents, adding an extra layer of safety to loading dock operations.

- Meeting Standards

- Many safety regulations and standards mandate the use of trailer restraints to ensure a secure working environment. Employing restraints helps facilities comply with these regulations.

- Automation Compatibility

- Trailer restraint systems can often be integrated into overall dock automation, allowing for synchronized and efficient operations.